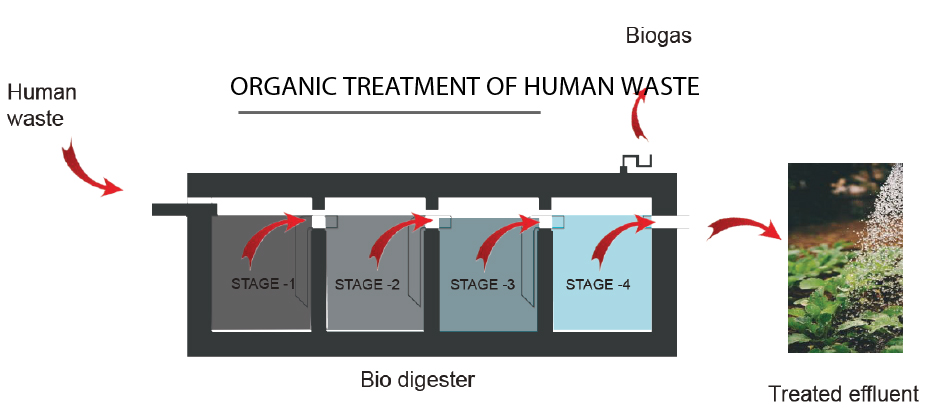

DRDO BIODIGESTER TECHNOLOGY is an eco-friendly solution for human waste disposal, developed by DRDE lab, Gwalior, of DRDO (Defence Research Development Organisation), Ministry of Defence, Government of India. Human waste (fecal matter) disposal is an ever-growing problem, leading to the threat of organic pollution and the risk of infectious diseases due to contamination of groundwater, food chain, and drinking water resources. We have some unfavorable conventional technologies like septic tank systems, which need to be evacuated frequently to preserve our environment for future generations.

The DRDO Biodigester technology developed by DRDO will be a game-changer in the sanitation sector in the years to come. The technology is now being used in Indian Railways (Bio toilets) and by the Armed Forces. The DRDO Biodigester tank is maintenance-free for a lifetime, as the anaerobic microbial Inoculums DRDO AMI is fed only once. It feeds on the fecal matter and multiplies by itself.

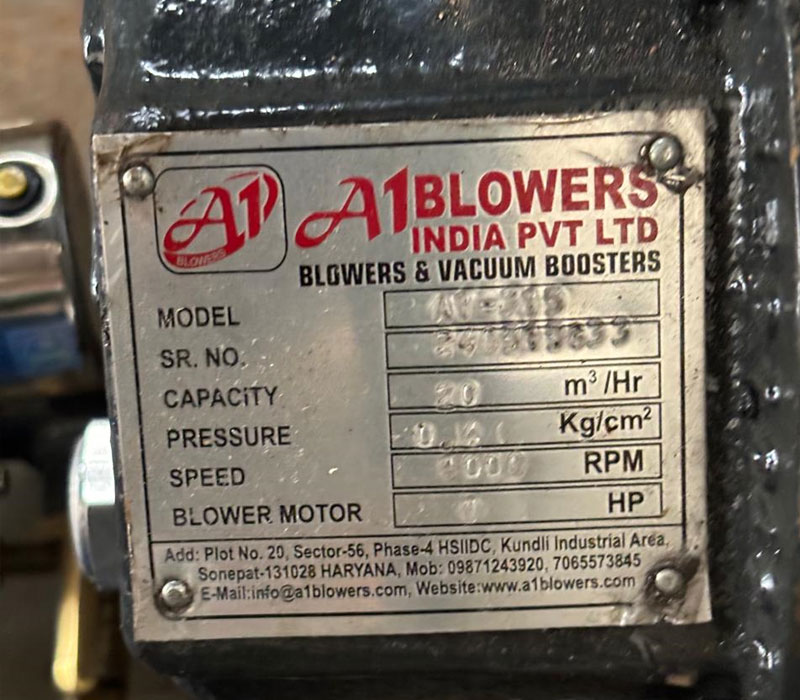

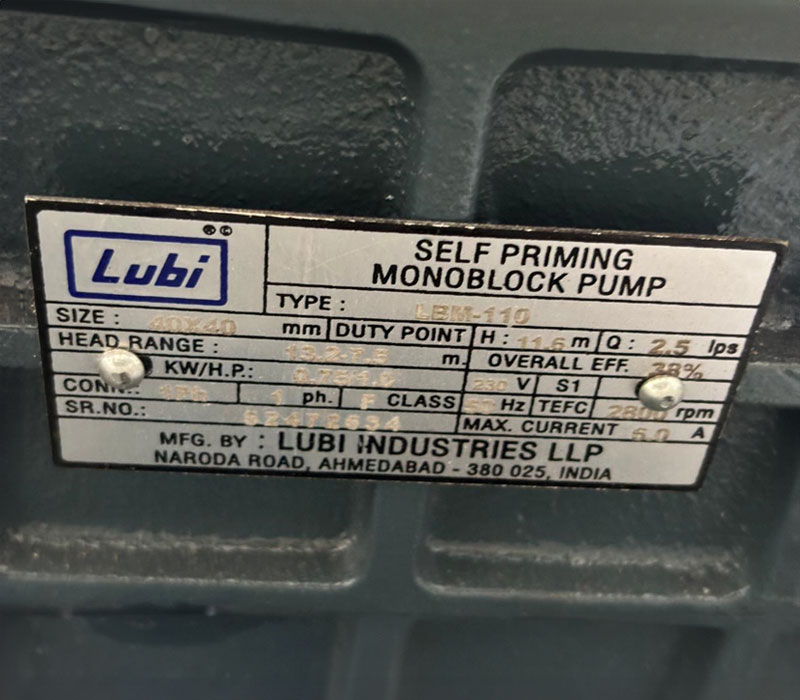

The DRDO Biodigester tanks can be customized based on the requirement of local conditions and can operate in temperatures ranging from minus (-) 20 degrees to plus (+) 50 degrees. All waste water generated from kitchen, oil and grease, soap solutions, toilet cleaners etc... can be fed into DRDO Biodigester without any detrimental effect to DRDO AMI, and final output will be clean water, without sludge ( as per the standards laid down by the KSPCB for soak pit drain ) As the biodigester have no moving parts it works, even without Electricity.

The technology can be used in independent houses, apartment complexes, food processing industries, hospitals, farms, schools & other commercial institutions, as BIO STP adhering to the standards, fixed by state pollution control Board.

Bio Pod™️ is a specially designed fermentation tank with provision of inlet for human waste and outlet for treated effluent which is odour-less and colour-less.

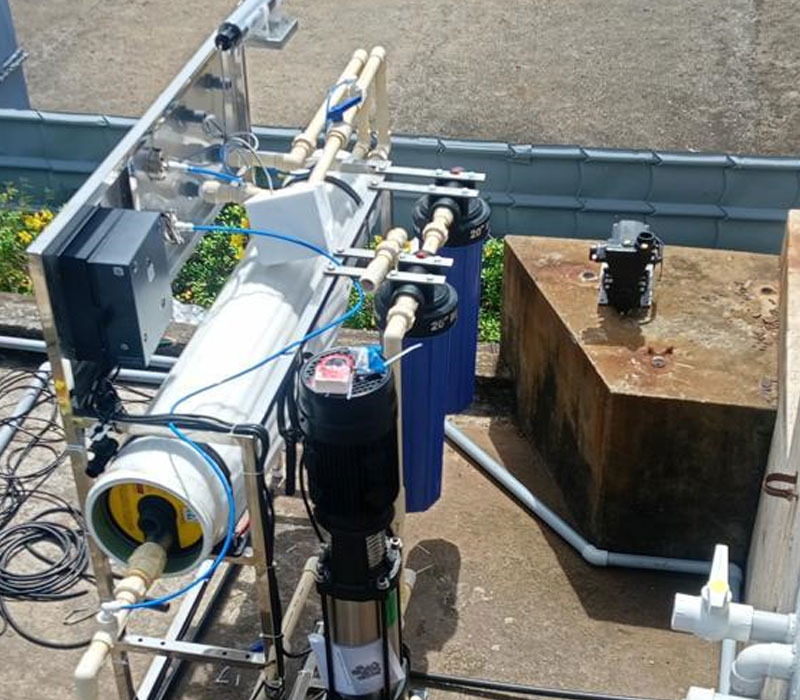

Construction of RCC tanks The capacity and volume of tanks decided by No of toilets, category of building.

Plumbing and biomatrix lining work, gas vent, oil & grease separator, post filtration arrangement inside the baffle walls.

Bacteria charging, DRDO AMI batch meets quality guidelines of DRDE Gwalior (DRDE/BD/TD Version 3) and inspection chamber grill fixing and maintaining tank in anaerobic conditions.

DRDO Biodigester is ready for usage. Final effluents is clean water conform to the standards of KSPCB, coming through out let is drained into soak pit, bacteriological survey can be conducted during intervals of 120, 180 days.

How to build a bio digester and how it works.

How to managed waste water at home

This system is Eco- friendly as it does not require septic tank cleaning.

The Zero waste process